MOLDING MATTERS

Molding any materials with ideal mold temperature increases quality and extends design possibilities.

Roctool technologies make it happen.

We provide the most advanced Heat & Cool Technology

The Finest Plastics Surface Quality Ever

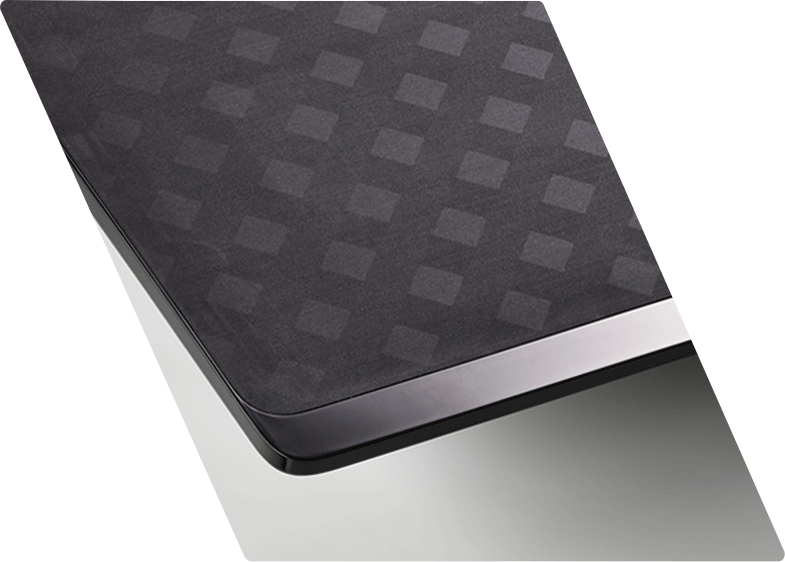

Plastics never looked so good. High gloss, detailed textures, improved mechanical properties, no surface defects, no sink marks, no visible weld lines, and no paint solutions. With Roctool technologies, plastics enter the world of High Definition.

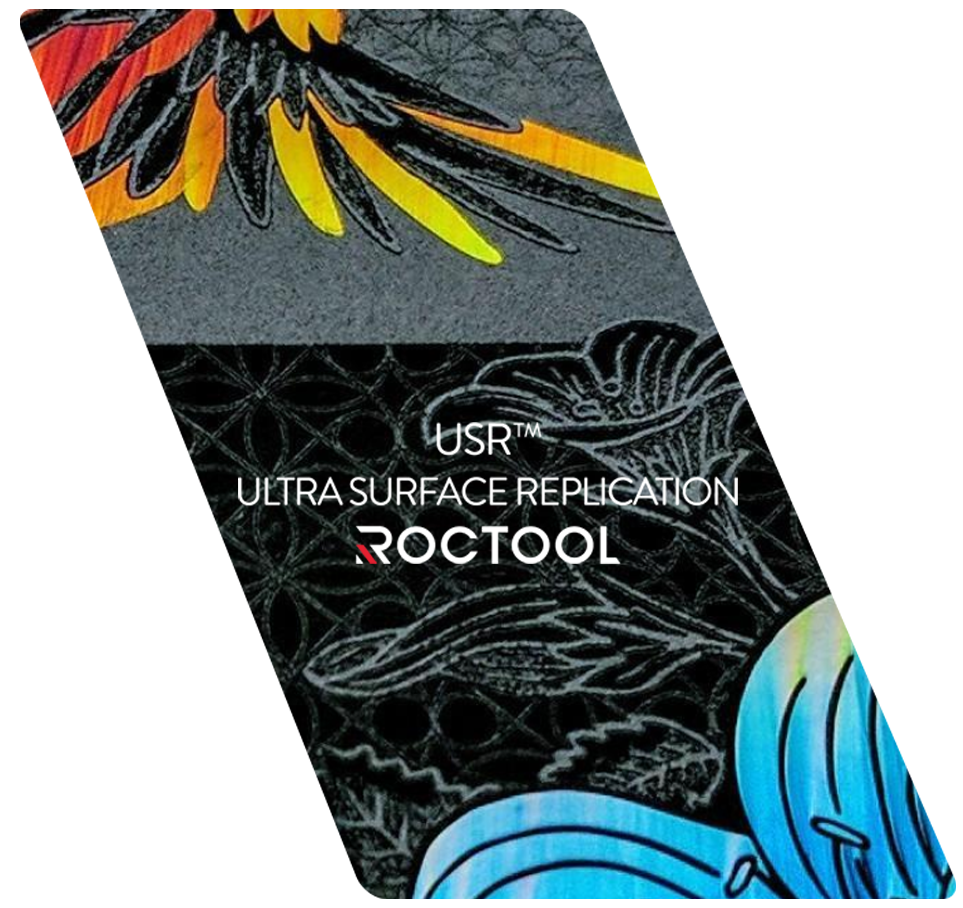

USR™ – Ultra Surface Replication

High definition reproduction directly from the mold surface to the part surface. Replication levels go to unchartered territories, at micro, nano and femto levels.

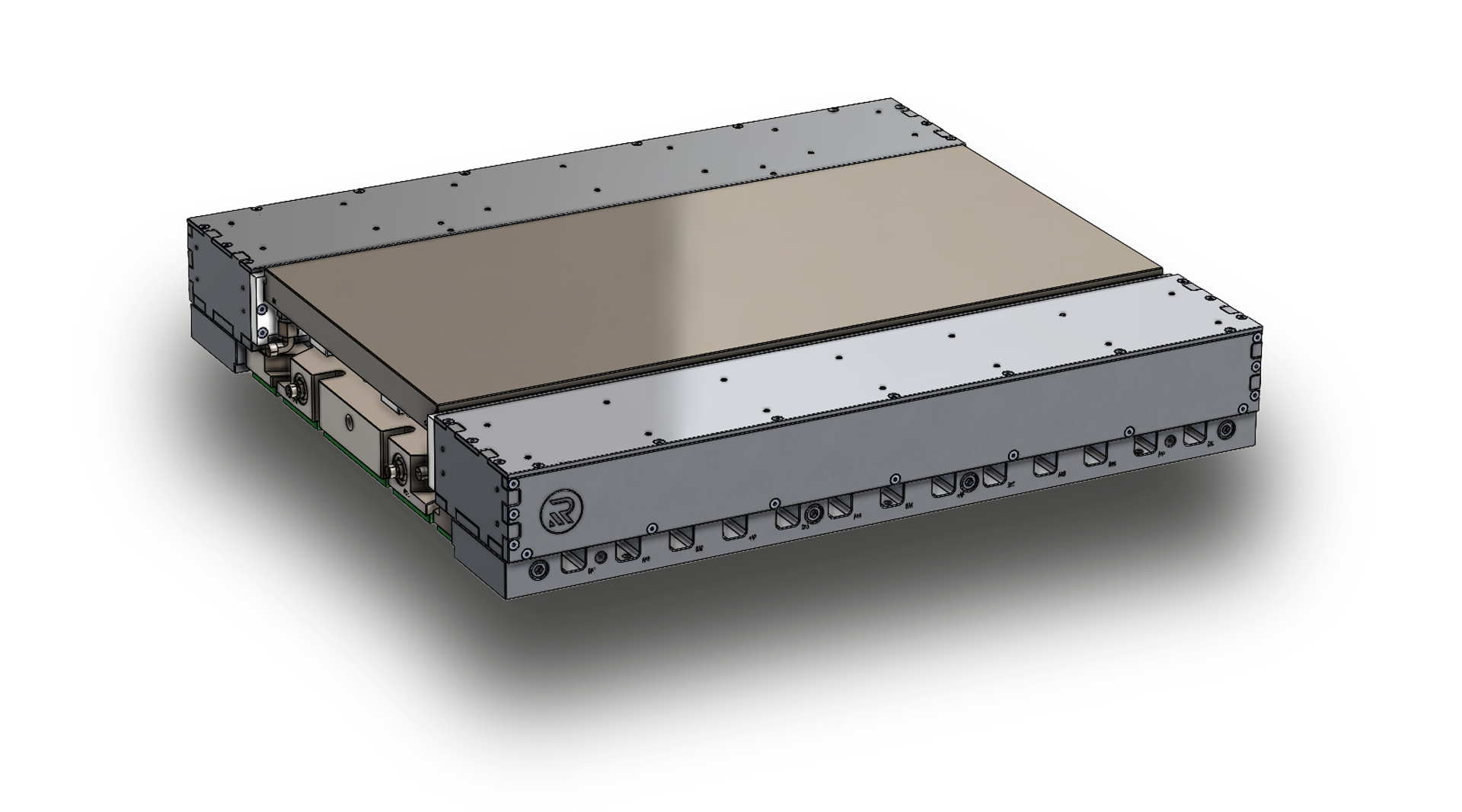

Advanced Compression Molding

- Fast.

- Temperature Control.

- High Heat.

Roctool induction molding technologies for composites make you forget other limited heating methods.

Our Technology

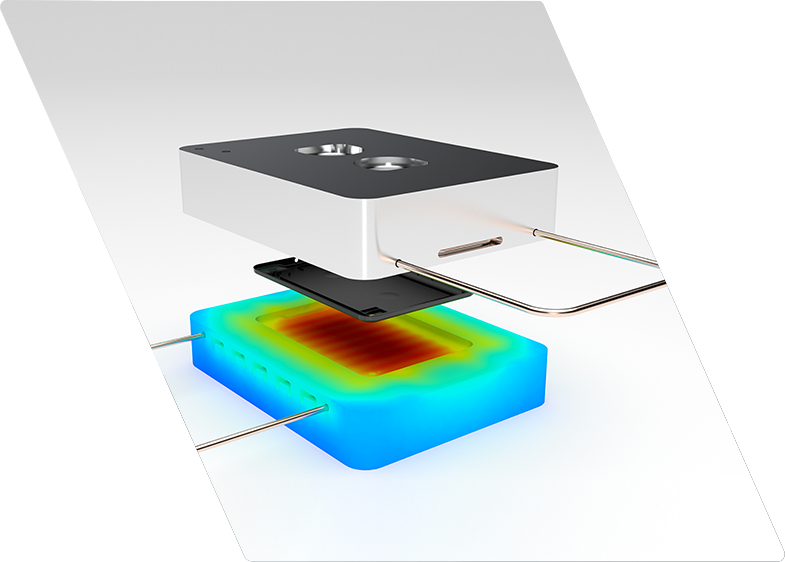

Compression Molding

Complete heating control for thermoset and thermoplastic compression. Quick cycle time with top surface quality.

Plastic Injection

Heating and cooling molds with Roctool process can radically reduce typical molded defects, increase surface quality and reduce cycle time.

HD Stories

We are proud to work with amazing product designers.

Here are some of the most compelling “HD Stories” that showcase some quality achievements on real products in production.

Work With US

Engineering

Simulation and tool design support.

Systems

Power units and peripherals.

Installation

Training and onsite support.

We're ready to work on a first feasibility

Send us a short brief for the production of your part, we’ll answer you within the next 48 hours.

Introducing High Definition Plastics

With Roctool’s Heat & Cool molding technologies and selected materials, we set up a new standard in the industry: High Definition Plastics. With Roctool high heat molding, the level of the tool surface replication goes up to 97.2%, providing product designers very premium looks, high gloss possibilities and matching the texture they initially targeted.

The flow increase with Roctool high heat molding technology unlocks design rules and pushes the limits in order to create thin wall applications.

See an overview of our performance rate database.

Latest News

ROCTOOL TECHNOLOGY

Heat & Cool system

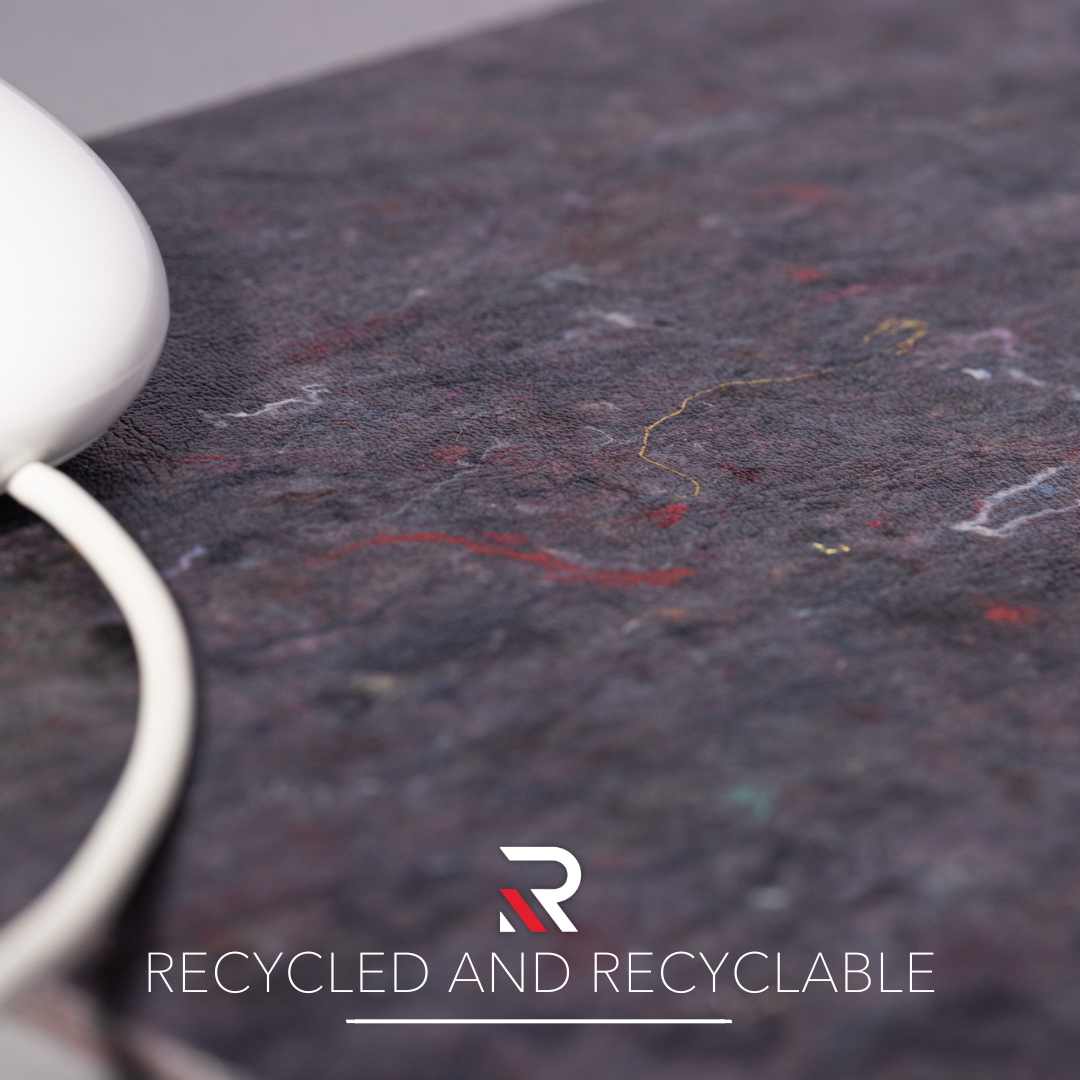

ECO-MOLDING™

Industry

Stories

Automotive, Aerospace, Electronics, Beauty, Consumer Goods, Medical

Work

with Us

Feasibility Study, Engineering, Analysis & Tool Design, Components, Installation